Advanced laser texturing

Innovative laser texturization

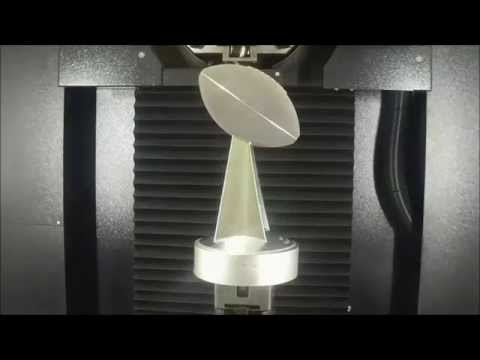

There are many different methods to change surfaces of metals to three-dimensional surface structures. At LES GRAVEURS, we use laser texturing for this purpose.

There are many different methods to change surfaces of metals to three-dimensional surface structures. At LES GRAVEURS, we use laser texturing for this purpose.

Laser texturing is a modern surface treatment that offers some new possibilities in the area of surface graining and structuring. These can be designed and produced very easily in tool molds.

The modern technology brings with it a number of advantages, especially in comparison to classic processes. Laser texturing is also an absolute pioneer, especially when it comes to process reliability, cost-effectiveness and ecology. However, processing with a laser turns it into a completely digitalized process chain that adapts even better to your requirements.

Advantages over other surface treatments

In contrast to other common surface treatments, modern laser texturing has many advantages:

- Exclusively digital process

Machining by the laser is done exclusively digitally and everything is done in a single work process. This makes the entire process much more precise, reliable and repeatable, which was not possible before compared to other machining methods. In addition, the desired result can be viewed before the actual production, so that errors can be detected more quickly and rectified earlier. This can also reduce the cost of producing prototypes or design samples, as they can be laser textured directly without incurring tooling costs at this still early stage. It is therefore an overall fast process with short production times. - Wide range of material usage

Laser texturing means that there are virtually no limits to what you can do, especially when it comes to the use of materials for the workpieces. Lasers can use an enormously wide range of materials. These include aluminum, copper, steel, carbide, brass, ceramics, plastics and many more. - Modern and environmentally friendly surface finishing

The progressiveness of laser texturing is particularly evident when compared to the classic surface processing methods. In the classic processes, the workpieces are eroded, blasted or have been processed with the manual etching method. Laser texturing, on the other hand, does not use chemicals or other harmful agents, so it is much more environmentally friendly. - Unlimited design possibilities of the texture

Not only in terms of material use, you have an infinite number of design possibilities. The design possibilities of the texture are also unlimited. Due to the particularly high precision provided by laser processing, workpieces can also be processed in a very filigree manner. Your concrete and individual ideas can thus be comprehensively realized.

Overall, laser texturing produces a recognizably better end product that is also faster and more cost-effective for you to manufacture.

FAQ – Modern Laser Texturing

What is laser texturing?

Laser texturing is a modern surface treatment method where a laser is used to create three-dimensional structures on material surfaces. This technology allows for the precise, digital creation of complex and intricate surface textures without the use of chemicals or manual processes.

What are the advantages of laser texturing?

Laser texturing offers many advantages, including digital process control for particularly precise and rapid processing. The entire process occurs in a single step, allowing early detection and correction of errors. Additionally, it works with a wide range of materials and is more environmentally friendly compared to traditional methods, as it avoids the use of harmful chemicals.

What materials can be laser textured?

Laser texturing can be applied to a variety of materials, including aluminum, copper, steel, carbide, brass, ceramics, and plastics. This versatility makes the process particularly attractive for various industries and applications.

What are the applications of laser texturing?

Laser texturing is used in various industries, including the automotive industry, medical technology, consumer goods, and electronics. It is particularly suitable for surface refinement of tool molds, prototype production, design patterns, and industrial applications requiring high precision.

How environmentally friendly is laser texturing?

Compared to traditional methods like etching or blasting, laser texturing is significantly more environmentally friendly. It does not use chemicals or harmful substances, reducing environmental impact while improving the efficiency of the production process.

Contact Us

Our team looks forward to your inquiries and will be happy to develop individual demand solutions with you.